Armil CFS industrial furnaces for investment casting range from our pre-engineered Tru-Heat® gas fired box burnout furnaces and preheat furnaces to custom pusher furnace and roller hearth systems that can include features such as temperature uniformity to +/- 5°F, pressure control, oxygen trim, NADCAP data collection, full automation, recuperation, and emission compliance / control as specified by our customers.

Investment casting furnaces such as the pusher, roller hearth, box burnout, and box preheat furnaces below are remarkably durable and rugged for years and years of hard work within industrial settings. Efficient afterburners are available with all furnaces, capable of meeting the most stringent regulations.

Armil not only designs and manufactures investment casting furnaces – we deliver and install them in order to ensure that your new industrial furnace will operate correctly the first time it roars to life in your shop or factory setting. Armil CFS has service personnel available to service any equipment in the field. American-made investment casting furnaces from Armil CFS – innovation, service and performance you can count on when things get really hot.

Please click on the images below to see more photos of each investment casting furnace offered on this page. You can Contact US with questions or if you wish to discuss our products.

Tru-Heat® Gas Fired Burnout Furnace

- Work Chamber: 72” W x 72”D x 36”T

- Temp Range: 450F to 2,200°F

- Uniformity: +/- 25°F DOWNLOAD BROCHURE

Tru-Heat® FastFire Wax Recovery Furnace

- For flashfire applications

- Integral Inert Gas Extinguishing Chamber for wax reclamation

- Operating temp range: 450°F to 2200°F

- Uniformity: +/- 25°F

- Integral Afterburner System

- Manual or power driven car

- Custom hearth configurations DOWNLOAD BROCHURE

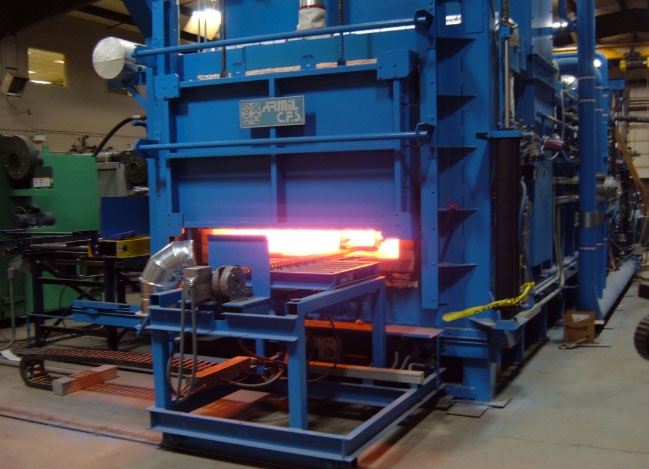

Gas Fired Pusher Furnace

- Recuperative combustion system and automated tray return conveyor

- Pre-Heated Air: 800°F

- Work Chamber: 30 Trays 30” x 20”

- Temp Range: 1800°F - 2100°F

- Temp Uniformity: +/- 25°F

Roller Hearth Burnout Furnace

- Work Chamber: 20 Trays 40” x 40”

- Temp Range: 600°F - 1500°F

- Temp Uniformity: +/- 25°F

- Afterburner Temp: 1650°F

Shuttle Car Bottom Burnout Furnace

- Work Chamber: 9’ W x 9’D x 50”T

- Temp Range: 400°F to 1,800°F

- Uniformity: +/- 25°F

- Afterburner Temp: 1650°F