Industrial Furnaces

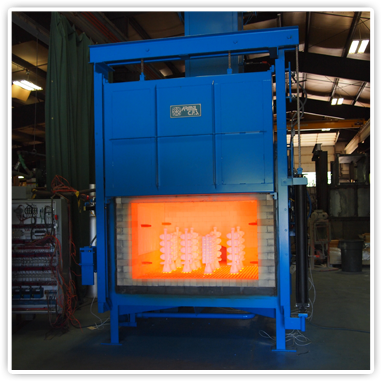

Armil CFS manufactures high temperature furnaces serving a wide range of industries. From pre-engineered Tru-Heat® box furnaces to custom designed furnace lines, Armil CFS furnaces encompass the latest in combustion and control technology, efficient refractory materials and are built to deliver in the toughest industrial environments.

Industries Served:

- Investment casting (Box Preheat, Box Dewax, Pusher Furnaces, Roller Hearth Furnaces, Flash Fire)

- Test Furnaces (Vertical and Horizontal Test Furnaces)

- Heat Treatment (Box Furnaces, Car Bottom Furnaces, Pit Furnaces, Roller Hearth Furnaces, Rotary Retort Furnaces, Screw Hearth Furnaces)

- Forging (Box Furnaces, Car Bottom Furnaces, Slot Forge Furnaces)

- Incineration (Box furnaces, Oxidizers, Cremation Furnaces)

- Ceramics (Shuttle Kilns, Box Kilns)

Types of Furnaces

Investment Casting Furnaces

Armil CFS industrial furnaces for investment casting range from our pre-engineered Tru-Heat® gas fired box burnout furnaces and preheat furnaces to custom pusher furnace and roller hearth systems that can include features such as temperature uniformity to +/- 5°F, pressure and airflow control systems, NADCAP data collection, full automation, and emission compliance / control as specified by our customers. Armil CFS pusher, roller hearth, box burnout, and box preheat furnaces are remarkably durable and rugged, built for years and years of hard work within industrial settings.

EO5 Test Furnaces

Armil CFS Vertical Test furnaces perform fire resistance tests on panels mounted vertically in a heavy duty refractory lined frame. Horizontal Test furnaces perform fire resistance tests on assemblies mounted horizontally over the furnace. Furnaces can be designed to perform both types of tests. Heavy duty construction ensure that Armil CFS high temp furnaces for materials testing will deliver reliable results and maximum temperature for years to come.

Box Industrial Furnaces

Armil CFS manufactures box furnaces ranging from our pre-engineered Tru-Heat® line to custom engineered box furnace systems that can include temperature ranges of +/- 5°F, emission compliance / control, pressure control, oxygen trim, full automation, recuperation, and NADCAP data collection. All Armil furnace systems are engineered using combustion and control equipment from leading manufactures. Refractory is installed by skilled and experienced bricklayers.

Forging Furnaces

Armil CFS furnaces range from our pre-engineered Tru-Heat® line to custom systems that can include temperature uniformity to +/- 5°F, NADCAP data collection, full automation, recuperation, pressure control, high-strength blowers, and emission compliance / control. Both our box forging furnaces and slot forging furnace designs can be engineered to reach process temperatures of 2,450°F.

Heat Treating Furnaces

Armil CFS heat treating furnaces range from our pre-engineered Tru-Heat® line to custom systems that can include pressure control, oxygen trim, temperature uniformity and operating temperatures of +/- 5°F, NADCAP data collection, full automation, recuperation, and emission compliance / control. Box, furnaces, car bottom, lift off, rotary retort, roller hearth, and walking beam styles are available. Our engineering team can work with your staff to devise an industrial furnace system that is just right for your shop or facility needs.

Cremation Furnaces

Cremation Systems manufactures cremation equipment in South Holland, IL. We are a division of Armil CFS, Inc., a 52 year old manufacturer of industrial furnaces for a variety of industries. Utilizing our experience, we have been able to produce a cremation retort that operates with greater efficiencies then comparable cremation equipment produced in the U.S.A. Our CFS 2300 cremation retort is suited for businesses of varying sizes and constructed to fit through a standard 8’ x 8’ door.

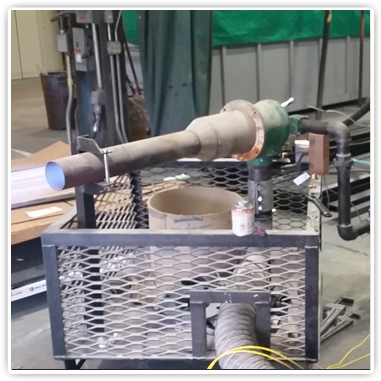

Packaged Burner System

Armil CFS Combustion Skids, Burner Skids and Packaged Burner Systems are pre-piped, pre-wired and skid mounted for flexible applications to meet your portable or site-specific applications. Utilizing the leading manufactures burners and controls our systems are designed to operate on natural gas, propane, and fuel oil. Applications for this type of combustion system include refractory dry-out, process heating, foundry ladle heaters / preheaters, and portability applications for remote use.

Armil not only designs and manufactures custom industrial furnaces – we deliver and install them. Armil CFS has service personnel available to service equipment in the field.

American-made furnaces from Armil CFS – innovation, service and performance you can count on when things get really hot.