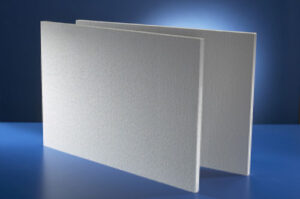

Fiberfrax Ceramic Fiber Boards

Fiberfrax ceramic fiber boards are manufactured through a vacuum forming process to offer low thermal conductivity, high temperature stability, uniform density, and excellent resistance to chemical attack and thermal shock. The rigidity and modulus of rupture for these fiber products make them strong and self-supporting, yet lightweight and easy to cut or fabricate. Most ceramic fiber insulation boards contain small amounts of organic binders and inorganic binders that will burn out between 450°F and 600°F during initial heat up. Armil CFS offers both standard boards and boards that have the binders already burned out.

*Exceptions include hydrofluoric, phosphoric, hydrochloric, sulfuric acids, as well as concentrated alkalis.

High Temperature Insulating Applications

Fiberfrax® Duraboard ceramic fiber boards are used for a variety of high temperature insulating applications up to 3000°F. All Duraboard ceramic fiber boards are manufactured from high purity Fiberfrax® alumina silica ceramic fibers.

These alumina silica boards are a healthier, safer alternative to asbestos boards and work well as self-supporting refractory lining or backup insulation. Fiberfrax Duraboard products can be used in a number of high temperature insulation applications such as kilns, chimney linings and flues, industrial furnaces, pizza ovens, combustion chamber liners, and more with minimal thermal shrinkage. Fiberfrax® Duraboards are resistant to oxidation and reduction and offer Low thermal conductivity and heat storage with continuous use.

AirCER High Alumina Boards

AirCER are engineered ceramic fiber insulation materials often used as a superior alternative to conventional vacuum-formed ceramic fiber shapes and castable products.

AirCer products are available in formulations for use at temperatures up to 3200°F. AirCer products offer superior strength, erosion resistance, high temperature stability and are often used in extremely harsh environments (i.e., areas of combustion). AirCER products are available in boards, cylinders, and custom shapes.

Here are some of the technical specifications for our fiber products:

- Technical Specs – to 2600°F(PDF)

- Technical Specs above 2600°F(PDF)

- Technical Specs – low organic boards(PDF)

- Ceramic Fiber Boards – general (PDF)

Armil CFS, Inc. has been designing, manufacturing, installing, and repairing furnaces, kilns, ovens, and other high temperature process equipment for more the 48 years. Armil CFS distributes and installs refractory, high-temperature insulation, combustion equipment, and process controls manufactured by industry leaders. Learn more about our Industrial furnaces and refractory materials such as ceramic fiber blankets, Insulating boards, heat shields, and other thermal insulation materials today.