Marinite is used in the Chemical and Petrochemical industries and is commonly used in structural insulation enclosures for pumps, valves, heat exchangers and more.

Marinite is used in the Chemical and Petrochemical industries and is commonly used in structural insulation enclosures for pumps, valves, heat exchangers and more.

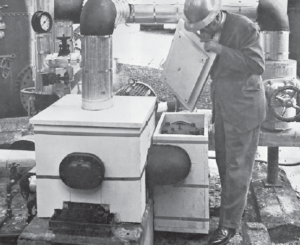

Marinite structural insulation enclosures insulate complicated shapes and permit easy access for periodic control and maintenance as in this refinery. Pump and single strainers require periodic access for maintenance and cleaning. Marinite housings retain heat, provide easy accessibility, and circumvent the problem of fitting insulation to irregular surfaces.

It is often simpler to build a Marinite enclosure around a complicated piece of equipment than to insulate the individual surfaces. This applies to pumps, valves, heat exchangers and similar equipment. Marinite is ideal for enclosing equipment like pumps and strainers that require periodic access for oiling, cleaning or replacement.

The Marinite housings are held together with sheet metal screws or metal bands, and occasionally are packed with fibrous insulation. Top surfaces are better when sloped for drainage and painted to provide weather protection. Freeze-thaw conditions are harmful to Marinite exposed to the weather. On equipment that is continuously heated, freezing of absorbed moisture could not occur and weatherproofing is not a necessity.

Marinite boards combine high strength and easy fabrication. Marinite boards and fabricated shapes are used in a variety of heat processing, fire protection, and electrical resistance applications. Marinte I, Marinite P, Marinite A, and CS85 are available. Learn more about Marinite here.

Marinite® I Structural Insulation Enclosures.

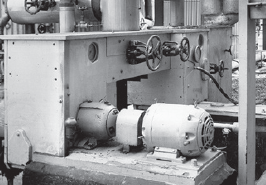

Pumps, valves, and instruments are enclosed in Marinite structure to minimize heat loss.

Pumps, valves, and instruments are enclosed in Marinite structure to minimize heat loss.

Heat exchanger covered and insulated with sheets of Marinite. Black paint has been applied over the Marinite.

Marinite enclosure insulates and protects steam control cabinet containing long bank of valves and steam piping. Marinite reduces heat loss, permits easy access for control or repair, and avoids complex problem of insulating individual surfaces.

BNZ Materials manufactures and is a worldwide supplier of a range of specialty industrial insulations. Calcium silicate insulation has been manufactured continuously for more than 60 years.

In addition to the Marinite calcium silicate product line, BNZ also manufactures Insulating Fire Brick and refractory specialties at the world’s most advanced IFB plant located in Zelienople, PA. Over sixteen types of IFB are available for use in applications from 2000°F to 3200°F to meet the specific needs of a variety of industries.

What are Structural Insulation Enclosures?

Structural Insulation Enclosures (SIE) are a type of building enclosure system designed to provide both structural support and insulation for a building. SIEs typically consist of an outer layer of load-bearing panels or sheathing, a layer of insulation, and an inner layer of panels or sheathing.

The outer layer of panels or sheathing provides the structural support for the building and is usually made of materials such as oriented strand board (OSB), plywood, or structural insulated panels (SIPs). The layer of insulation between the outer and inner layers helps to reduce heat transfer, providing a more energy-efficient building envelope.

One of the benefits of using a Structural Insulation Enclosure system is that it can help to reduce construction time and costs since it combines the functions of both structural support and insulation into one system. Additionally, SIEs can help to improve the overall energy efficiency of a building, which can result in lower heating and cooling costs over the life of the building.

What is Marinite?

Marinite is a type of fire-resistant board made from a mixture of inorganic materials and Portland cement. It was originally developed in the 1950s and was primarily used in industrial and marine applications where fire safety was critical.

Marinite boards are known for their excellent fire resistance, high strength, and thermal shock resistance. They are often used as insulation and cladding in high-temperature applications, such as furnaces, boilers, and kilns. Marinite boards are also commonly used in marine applications, such as shipboard bulkheads and fireproofing insulation.

Marinite boards come in various thicknesses and sizes and can be easily cut and shaped to fit specific applications. They are typically installed using mechanical fasteners or adhesive systems. Marinite boards can be left exposed, or they can be covered with a variety of finishes, such as paint, stucco, or ceramic tiles.

Armil CFS & Marinite Structural Insulation

Armil CFS offers a variety of Marinite® calcium silicate and Transite® fiber cement structural insulation boards. Armil CFS personnel install ceramic fiber coatings into a wide variety of high-temperature equipment. Please feel free to contact us to discuss your high-temperature applications.

Since 1968, Armil CFS has designed and manufactured high-temperature process equipment, including furnaces, kilns, and incineration equipment. In addition, Armil CFS is a distributor for leading high-temperature insulation and refractory products.